The power of FMCW lidar + scale: Why acquiring OURS lidar unlocks the commercialization of the Aurora Driver

February 26, 2021 | 2 min. read

There are some undeniable truths in life: death, taxes, and the fact that you can’t pursue self-driving vehicles if you don’t have lidar that has long-range sensing capabilities and a cost-effective way to scale.

When we acquired Blackmore in 2019, we said it would be a game changer for our ability to pursue autonomous trucking because FMCW lidar allows us to see further and faster than ever before. (Long-range sensing? Check!) Since then, we have moved quickly to deploy our trucks in Texas, outfitted with Aurora’s FirstLight Lidar, which allows us to see well beyond 300 meters, measures velocity instantaneously, and is interference-free. Plus, it’s purpose-built to meet the needs of the Aurora Driver, on Aurora’s timeline.

We focused on performance first, and now it’s time to scale. As we look to expand our fleet and commercialize our driverless trucks, FirstLight Lidar must be increasingly scalable—it needs to be smaller and less expensive, but just as powerful. To make that happen, we’re excited to announce that we’re acquiring OURS Technology, a lidar-on-a-chip company that will help us do just that. (Scalability? Check!) And in addition to their cutting-edge tech, we look forward to having their team join Aurora!

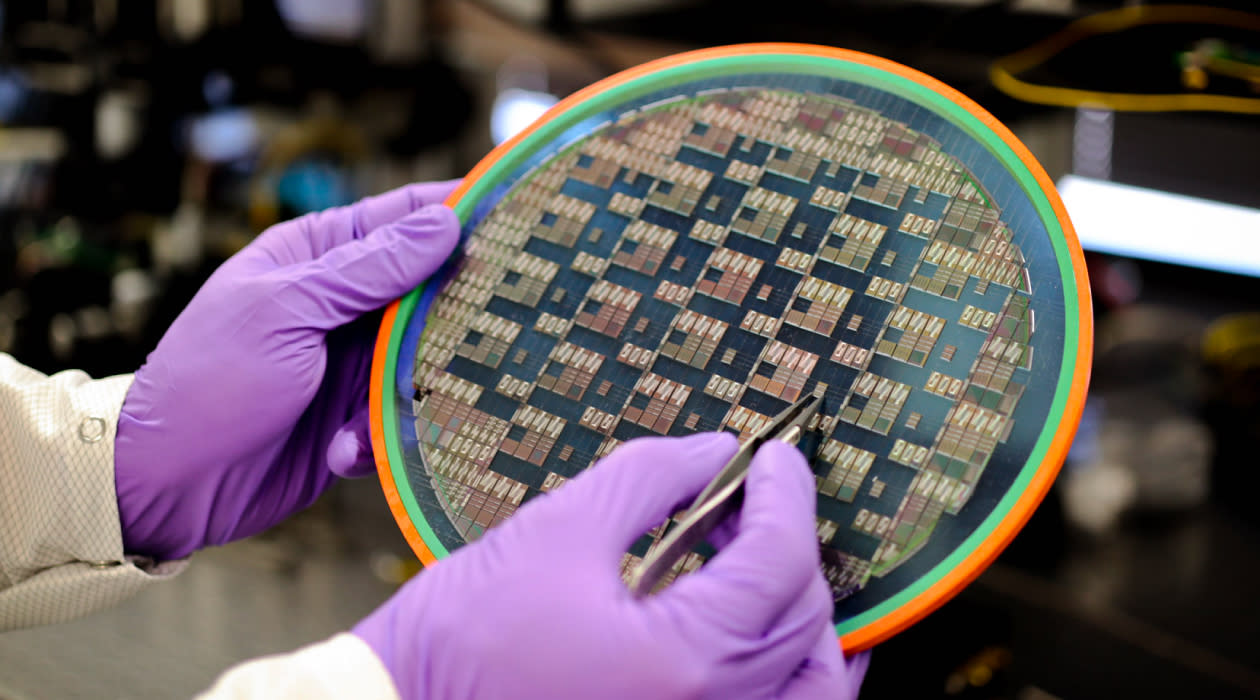

This is OURS’s latest generation lidar-on-a-chip. It combines the necessary components—including the solid-state beam steering system and FMCW transceiver. The technology reduces hundreds of photonics building blocks into this tiny, mass-producible chip.

OURS, like Aurora, has a thoughtful and speedy approach to integrated FMCW lidar development. A leader in integrated photonics, OURS’s proprietary design and development process has enabled it to produce four generations of lidar technology in just three years. Its fourth-generation lidar is massively smaller (one-tenth the size!) and cheaper, and this capability will enable Aurora to produce FirstLight at scale.

Here's how we accelerate our path to market with OURS's technology and team:

Drive costs down

Driven by integration and silicon photonics, our next-generation FirstLight system is expected to cost dramatically less, helping to evolve FirstLight into an automotive-grade commercial product that we can produce at scale.

Smaller size, with even more performance

Today's lidar is almost entirely mechanically steered, so OURS’s groundbreaking solid-state scanning mechanism is another lidar game-changer, as its lidar-on-chip method replaces bulky, unreliable, and expensive mechanical parts. This increases the reliability of our hardware and the uptime of the Aurora Driver, meaning we can handle more rides and deliver more goods, faster and more efficiently.

Flexibility to customize

OURS has the ability to rapidly customize and create new capabilities on chip unlike other developers who are often limited to foundries' off-the-shelf capabilities. This ability to customize gives us even more control of the lidar, while also providing us commercial flexibility to work with the right set of partners.

With the proprietary long-range capabilities of FirstLight, combined with our ability to scale the technology, Aurora has the only lidar solution that will unlock high-speed self-driving at scale, making FirstLight the highest-performance, automotive-grade lidar available for the driverless market. And as seen by how quickly we got FirstLight onto our trucks, we have the expertise to rapidly turn prototypes into scalable products. In the foreground, we see the lidar engine; in the background, we see it packaged into OURS’s FMCW lidar system. This enables packaging approaches similar to cameras—compact, robust, scalable, and affordable.

In the foreground, we see the lidar engine; in the background, we see it packaged into OURS’s FMCW lidar system. This enables packaging approaches similar to cameras—compact, robust, scalable, and affordable.

Of course, technology is only part of the equation. OURS is a highly technical and humble group of technologists who are passionate about their tech reaching multiple markets and millions of people. We’re glad to have them at Aurora!

This acquisition, similar to our other early foundational investments, enables us to move at a speed that others can not. Whether it’s our investment in lidar or our investment in our Virtual Testing Suite and platform-agnostic approach, we’ll continue to make intentional decisions that allow us to accelerate progress, bringing us closer to delivering this technology safely, quickly, and broadly.

Delivering the benefits of self-driving technology safely, quickly, and broadly.