Aurora Voices with Sen Lin

Meet Sen Lin, Aurora’s Silicon Photonics Director and a co-founder of OURS Technology

At the heart of Aurora’s technology and mission are the individuals behind it. In our series, Aurora Voices, we share the unique voices and stories of the people of Aurora, celebrating our backgrounds as well as personal and professional experiences.

Lidar sensors may be unfamiliar for many, but Sen Lin has been laser-focused (pun intended) on their vast potential since the beginning of his career. That focus led him to co-found a cutting-edge integrated photonics company, which produced four generations of lidar technology in just three years and was then acquired by Aurora.

As Aurora’s Silicon Photonics Director, Sen is responsible for developing integrated photonics solutions to enable mass production of our next-generation FirstLight Lidar. When Sen isn’t focused on photonics, he can be found in the Bay Area hiking or writing songs… about photons.

Tell us about how you became interested in lidar and why you founded OURS.

Inspired by innovators and entrepreneurs in Silicon Valley, I decided to pursue my PhD at UC Berkeley, where I had the privilege of working with Vladimir Stojanovic. He taught me the importance of systems engineering and always pushed me to set outrageous goals.

My research was focused on large-scale silicon photonics systems, an exciting field at the confluence of photonics, circuits, and systems. Scalability was (and still is) the greatest challenge to broadly integrating lidar in today’s technology. It was clear that leveraging silicon photonics to create solid-state lidar, an evolution that would make lidar mass-producible and more reliable, would be revolutionary. Spurred by this tough challenge, I went on to bring a group of passionate technologists together to found OURS Technology.

Could you explain, at a high level, what the OURS team built?

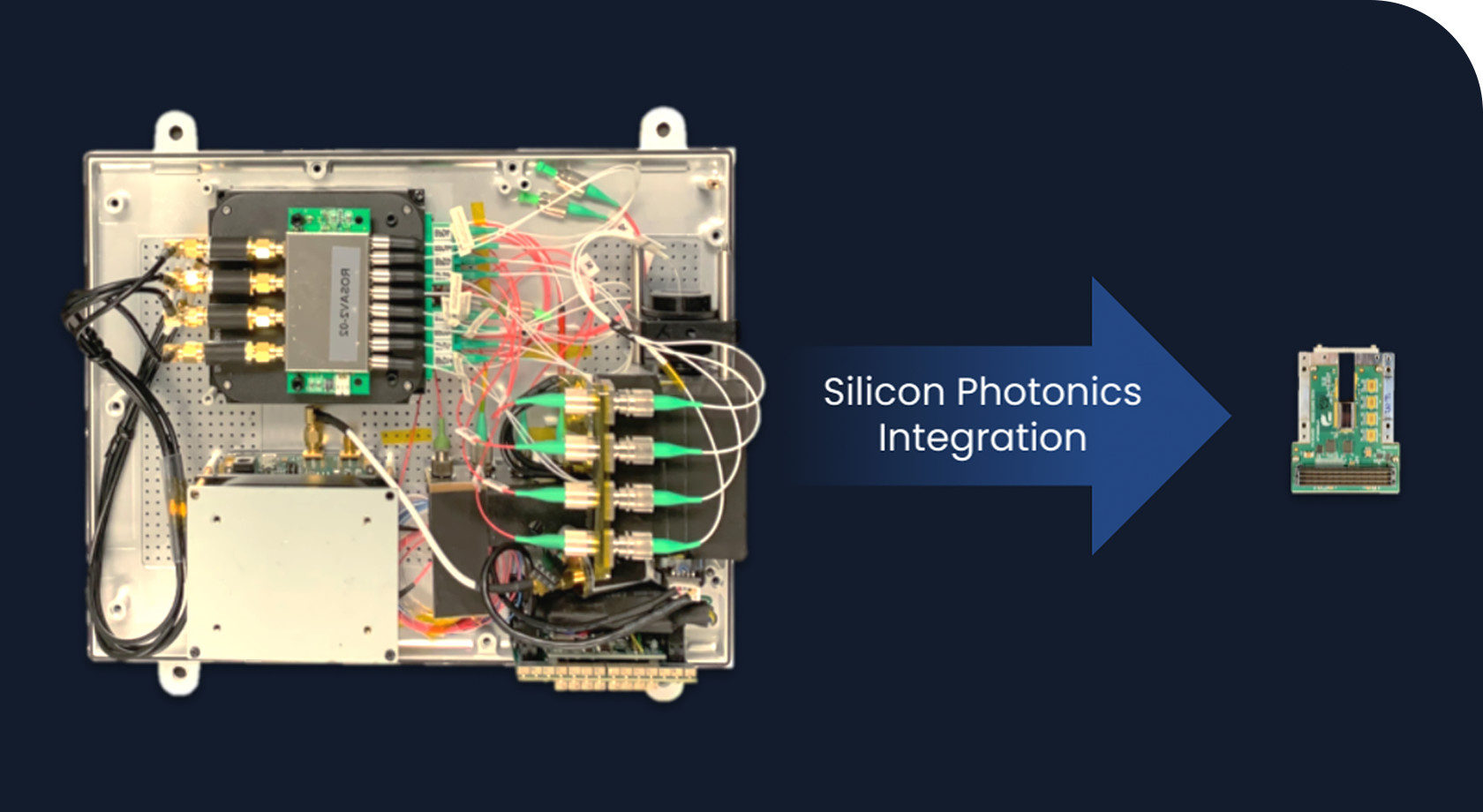

We focused on developing mass-producible automotive FMCW lidar solutions using silicon photonics. Over three years we prototyped several generations of FMCW lidar systems with significantly improved integration and manufacturability with each iteration. First, we demonstrated lidar systems with discrete fiber components, then we developed lidar systems with silicon photonic receivers. Finally, we built lidar systems with silicon photonic transceiver and solid-state scanning capabilities, paving the way towards a lidar-on-a-chip solution with ultimate scalability.

Tell us about the path that led you to Aurora. Why autonomous vehicles and why Aurora?

We’ve always been driven by the positive impact our lidar technology could have on the world. Self-driving presented the opportunity for our technology to reach the most markets and touch the most lives.

Three things stood out after meeting the Aurora team. First, Aurora had developed a robust and performant in-house FMCW lidar and we could help it rapidly scale and broadly deliver Aurora’s core technology. Second, we were impressed by Aurora’s leadership and team. Third, Aurora’s collaborative and supportive company culture was clear from the first conversation we had with the team.

Since we joined in February, the newly formed Photonic Integrated Circuits Solutions (PICS) team has been fully integrated. In three short months, we completed the technical integration process, helped define a new lidar roadmap and architecture, started designing several photonic chips specifically optimized for FirstLight lidar, and brought up a new photonics lab in Mountain View.

How does lidar-on-a-chip technology help scale FirstLight lidar? What is one of the toughest challenges you’re trying to solve?

Traditional lidar sensors rely on carefully threaded optical fibers. Leveraging silicon photonics we are able to integrate thousands of components and optical circuits onto a single silicon chip the size of a fingernail. Our lidar-on-a-chip technology reduces or even eliminates fibers in the system and makes our FirstLight lidar cheaper, more reliable, and more powerful.

The toughest part of developing this technology is coupling light onto silicon photonic chips without fibers, requiring precision smaller than one hundredth of the diameter of human hair. We are developing novel solutions that achieve this precision, while producing very high throughput with automation.

What’s a weekend in the life of Sen?

On weekends, I like to go on hikes with my wife. We also enjoy experimenting with different recipes–they always taste better after a long hike! One dish that we recently had fun making was stuffed lotus root and shrimp wontons.

You’re relentlessly focused on lidar. How have you brought some fun into your work?

In my first year of grad school, I spent a lot of time in the hardware engineering lab, so much so that at one point I decided to write a song about my experience. My roommate and I recorded a song about photolithography, carbon nanotubes, hydrofluoric acid, and the doom of Moore's law. We got hundreds of thousands of views in days!

Related (06)

May 31, 2023

Protecting our autonomous future

June 7, 2023

Aurora Voices with Lindsey Loewen

April 10, 2023

With Its Focus on Commercial Launch, Aurora Names Nat Beuse as Chief Safety Officer

February 9, 2023

Aurora Voices with Lance Underwood

August 30, 2023

Aurora Voices with Jason Leu

March 15, 2023